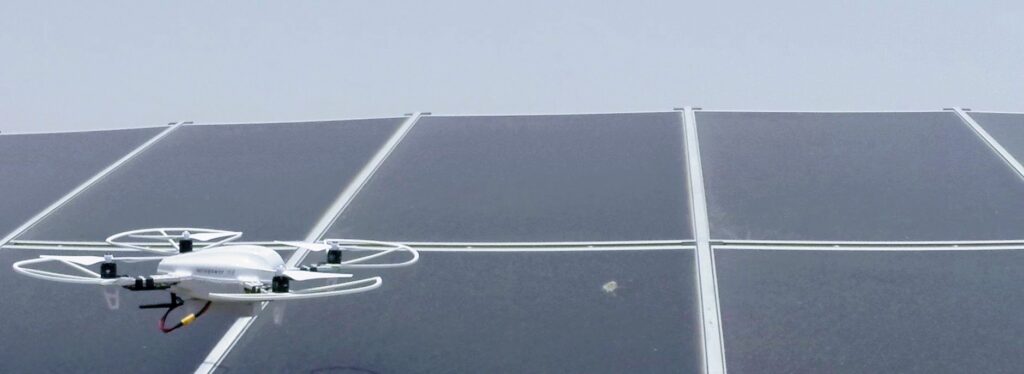

Patented Drone Cleaning with a Breeze

‘Aerial Power’ represents a patented method for automating drone-based cleaning. This technique utilizes a drone’s own airflow. When applied to solar farms, drones can offer an efficient and environmentally friendly approach to maintaining solar power production.

The unmanned aerial vehicle (UAV) does not aim for complete cleanliness on the glass surface of the solar panel. Instead, the primary objective is to generate more renewable energy while keeping maintenance costs low with Aerial Power.

The waterless cleaning process employed by the UAV is both quick and cost-efficient. Its operation also has minimal ecological impact. This supreme flexibility surpasses existing cleaning technologies, particularly in developing countries.

Pioneering Industries with Novel Drone Applications

Drones have been widely used for various applications such as inspection, film production, and goods delivery. However, Aerial Power is the first to utilize a drone’s airflow in autonomous flight for cleaning purposes. This patented method (US Pat. US 10,046,857 and international counterparts) leads to extended flight times and improved economics across numerous use cases:

Energy & Utilities ↗

Solar panels, mirrors, and CSP systems are prone to buildup and require frequent cleaning to maintain energy yield. In industry, filters, manufacturing equipment, and power grids can be difficult to access. In such cases, maneuverable drones present a practical solution.

Built Environment ↗

In transportation and infrastructure, for example, rail tracks or street signs affected by sandstorms, drone airflow presents an eco-friendly alternative. Car sensors, especially those reliant on optics, are susceptible to dust. UAVs can efficiently clean these from the outside.

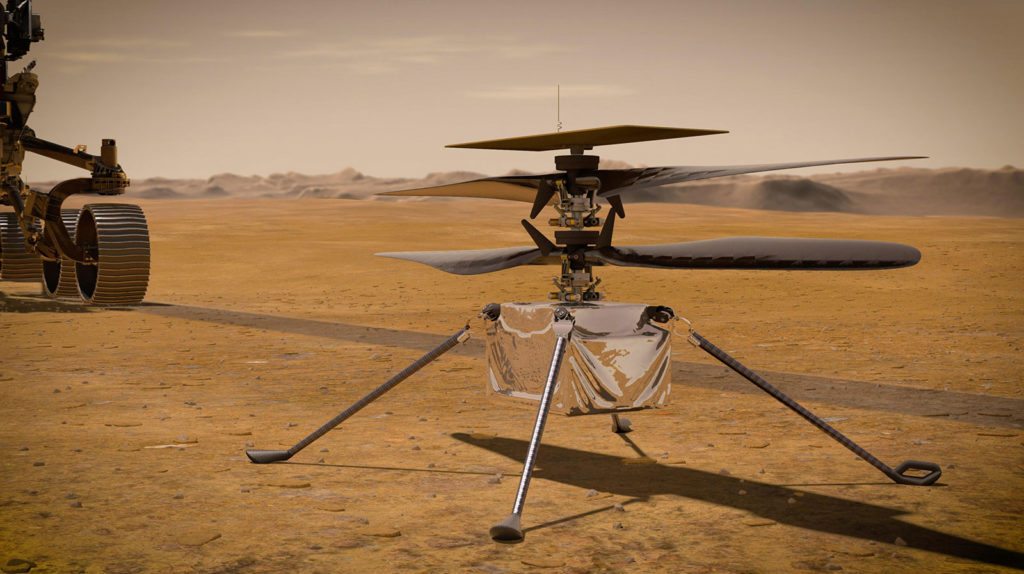

Space & Beyond ↗

Airflow cleaning has been validated on Mars: Winds clean solar panels on rovers and also cause soiling. Optimal sunlight penetration is vital for plant growth in greenhouses on Earth as well; waterless airflow cleaning is ideal in dry regions (photo: NASA/JPL-Caltech).

Agriculture & Greenhouses ↗

In arid regions, Aerial Power’s drone technology provides a waterless solution for maintaining greenhouse cleanliness. This patented method enhances sunlight penetration for crop growth, complementing traditional cleaning methods and promoting sustainable agriculture.

Research has demonstrated that utilizing the downdraft of the patented Aerial Power drone cleaning method can significantly increase the yield and viability of solar farms in arid regions of the world. In these areas, the primary factor that reduces panel efficiency is the accumulation of dust and sand on the surface of glass panels. The airflow cleaning method is set to impact the aforementioned industries.